Cleanroom, in manufacturing and research, is a dust-free working area with strict temperature and humidity control that is of vital importance in the manufacture of equipment sensitive to environmental contamination, such as components for electronic and aerospace systems. A typical cleanroom has an atmosphere-control system that rigidly regulates temperature and humidity and bars entrance, by means of filters, of all but minuscule contamination.

Daniel Holbrook of Marshall University, traces the origins of the cleanroom in his article ‘Controlling contamination: The origins of clean room technology’.

According to Daniel Holbrook, “Cleanroom technology is central to high tech manufacturing. Its development stems from the convergence of needs in several fields of manufacturing, health care, and military requirements. Small-sized mechanical and electro-mechanical devices brought problems with dirt and dust to the forefront, particularly during World War II. As electronics became a military and commercial staple, filtered and conditioned air, controlled procedures and behaviors, employee training, special uniforms, carefully selected construction design and materials, and physical isolation from other parts of the manufacturing facilities came together in the earliest cleanrooms.

Diversity in practices drove the demand for standards and fostered further developments. By the 1960s contamination control emerged as a distinct field, with clean room technology at its core. Thus established, the benefits of clean manufacturing spread to other fields and industries.”

To set up and maintain a cleanroom, an extensive list of products and systems are required. They include testing equipment, specialised consumables and apparel, cleaning equipment, etc. which reduce chances of contamination and ensure the environment inside the cleanroom is as per ISO-14644-1 / FED-STD-209E standards.

Furniture plays an important role too. Products such as Laboratory chairs, stools, and stainless steel tables are specially designed for use in semiconductor, bioscience, pharmaceutical, and board manufacturing in cleanrooms.

Cleanrooms are used across industries – for manufacture and testing in pharma, clinical, chemical, biotechnology, defence, healthcare, electronics, food and other industries. Messung Workplace Technology partners with clients in these sectors to help create cleanrooms that meet ISO 5/Class 100/ISO-14644-1 standards.

Currently, Messung Workplace Technology offers stainless steel tables, SS chairs & stools, SS trolleys, storage racks, lab tables, lab tables with drawers as per ISO-14644-1 cleanroom criteria, and provide unmatched ergonomics and convenience in cleanroom applications.

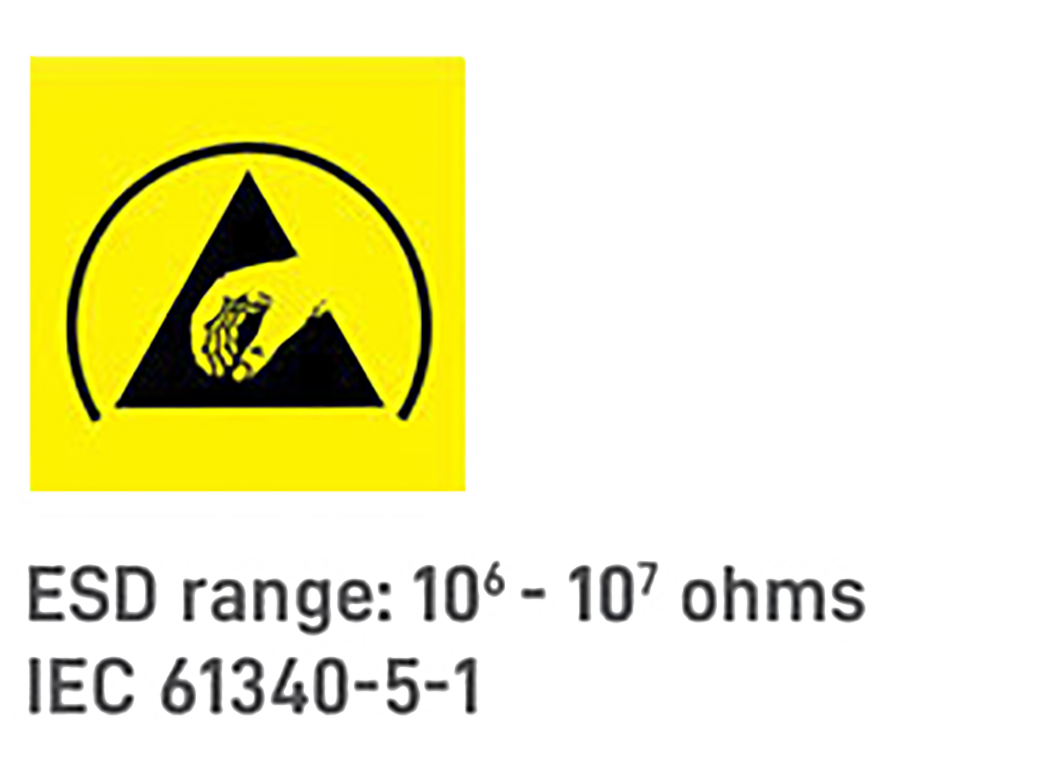

Messung Workplace Technology also offers Japanese-made ESD-safe cleanroom chairs and stools from Uchida. These innovative, high-quality laboratory chairs are certified by ISO class 100, and are designed and manufactured to fulfil basic cleanroom criteria.

The importance of furniture in cleanrooms hardly needs to be emphasised. It not only affects the critical quality of the work, it impacts employee health. Messung has four decades of experience in industry, and indepth understanding of work conditions, compliances and global standards. Messung’s AFM-PLUS series of sleek ESD workstations, ESD chairs and ESD rack storage is already well-accepted in the Indian market due to the world-class looks and features.

For scientific research or specialised industrial production of products such as electronics, pharmaceutical products, medical equipment, etc., where cleanrooms are essential, Messung’s cleanroom systems provide efficient and cost-effective solutions. What is more, Messung studies customer requirements and can tailor the best, most relevant solution for customised efficacy. Call Messung Workplace Technology today.

+91 8624908528

+91 20 6696 1100

info@messung.com

Design by: Optimist Brand Design LLP

Messung Global Connect Pvt. Ltd.

(An ISO 14001:2015 Certified Company)

World Trade Center, Tower ‘II’, Office No. 420,

Kharadi, Pune 411 014, India.

© Copyright 2025 Messung Workplace Technology